It is used to increase the profits of the company by saving money on labor costs. Actual labor costs may differ from budgeted costs due to differences in rate and efficiency. Hence, variance arises due to the difference between actual time worked and the total hours that should have been worked. This calculator simplifies the process of determining labor efficiency, providing valuable insights for managers and business analysts looking to optimize labor usage and control costs. Direct labor efficiency variance pertain to the difference arising from employing more labor hours than planned.

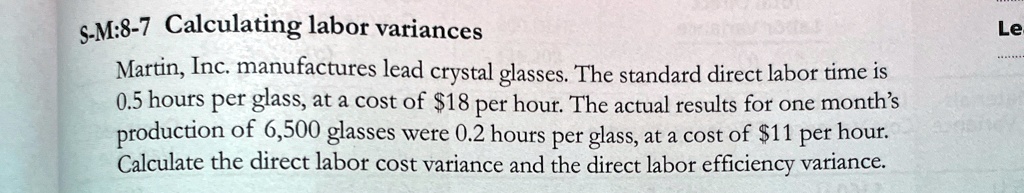

Computing Direct Labor Variance

This calculator assists in quantifying the difference between the labor hours spent and the ideal or expected hours, providing insight into the efficiency of labor utilization. Companies can reduce Direct Labor Mix Variance by more accurately predicting labor needs, using flexible staffing solutions, and making use of labor-saving technology. Additionally, it is important to ensure that labor costs are monitored and managed effectively. Direct Labor Mix Variance typically occurs when the actual labor mix used in production is different from what was budgeted or anticipated. Direct Labor Mix Variance is the difference between the budgeted labor mix and the actual labor mix used in production, which can lead to an over- or under-utilization of resources.

How does Direct Labor Mix Variance occur?

Typically, the hours of labor employed are more likely to be under management’s control than the rates that are paid. For this reason, labor efficiency variances are generally watched more closely than labor rate variances. Labor rate variance arises when labor is paid at a rate that differs from the standard wage rate. Labor efficiency variance arises when the actual hours worked vary from standard, resulting in a higher or lower standard time recorded for a given output. It occurs when the actual hours worked are more than the standard hours allotted for a specific level of production.

Calculation Formula

- It is crucial as it flags discrepancies between planned and actual labor hours, pinpointing inefficiencies.

- Direct Labor Mix Variance is defined as the difference between the exact amount of labor needed to manufacture a product and the actual amount of labor used for that product.

- It is a very important tool for management as it provides the management with a very close look at the efficiency of labor work.

- For Jerry’s Ice Cream, the standard allows for 0.10labor hours per unit of production.

- Additionally the variance is sometimes referred to as the direct labor usage variance or the direct labor quantity variance.

- Measuring the efficiency of the labor department is as important as any other task.

In such cases, the negative variance indicates lower efficiency, as more time than expected was needed to complete the work. We have demonstrated how important it is for managers to beaware not only of the cost of labor, but also of the differencesbetween budgeted labor costs and actual labor costs. This awarenesshelps managers make decisions that protect the financial health oftheir companies.

Table of Contents

To calculate Direct Labor Mix Variance you must first identify the exact amount of labor it requires to produce a product. Later in Part 6 we will discuss what to do with the balances in the direct labor variance accounts under the heading What To Do With Variance Amounts. An example is when a highly paid worker performs a low-level task, which influences labor how much cash can you withdraw from your bank efficiency variance. A negative variance indicates that more hours were worked than planned, leading to an unfavorable variance of $200. Measuring the efficiency of the labor department is as important as any other task. Figure 10.7 contains some possible explanations for the laborrate variance (left panel) and labor efficiency variance (rightpanel).

Do you own a business?

Labor mix variance is the difference between the actual mix of labor and standard mix, caused by hiring or training costs. The direct labor efficiency variance is similar in concept to direct material quantity variance. Understanding labor efficiency variance is crucial for managers to control labor costs, improve scheduling, and enhance operational efficiency.

The direct labor variance is the difference between the actual labor hours used for production and the standard labor hours allowed for production on the standard labor hour rate. This information gives the management a way tomonitor and control production costs. It is necessary to analyze direct labor efficiency variance in the context of relevant factors, for example, direct labor rate variance and direct material price variance. It is quite possible that unfavorable direct labor efficiency variance is simply the result of, for example, low quality material being procured or low skilled workers being hired. In case of low quality direct material, the direct material price variance will likely be favorable and in the later case, the direct labor rate variance will probably be favorable; both at the expense of direct labor efficiency variance. Controlling these costs is essential, and one of the key ways to do this is through calculating direct labor efficiency variance.

Calculating DLYV can help organizations better control their labor costs, optimize production processes, and improve overall profitability. It also provides insights into the effectiveness of human resource management initiatives. Other reasons of labor rate variance include the payment of overtime premium to workers in case of rush orders with aggressive delivery dates and relying on inaccurate or incomplete data at the time of setting direct labor standards. If the total actual cost incurred is less than the total standard cost, the variance is favorable. Labor yield variance arises when there is a variation in actual output from standard. Since this measures the performance of workers, it may be caused by worker deficiencies or by poor production methods.